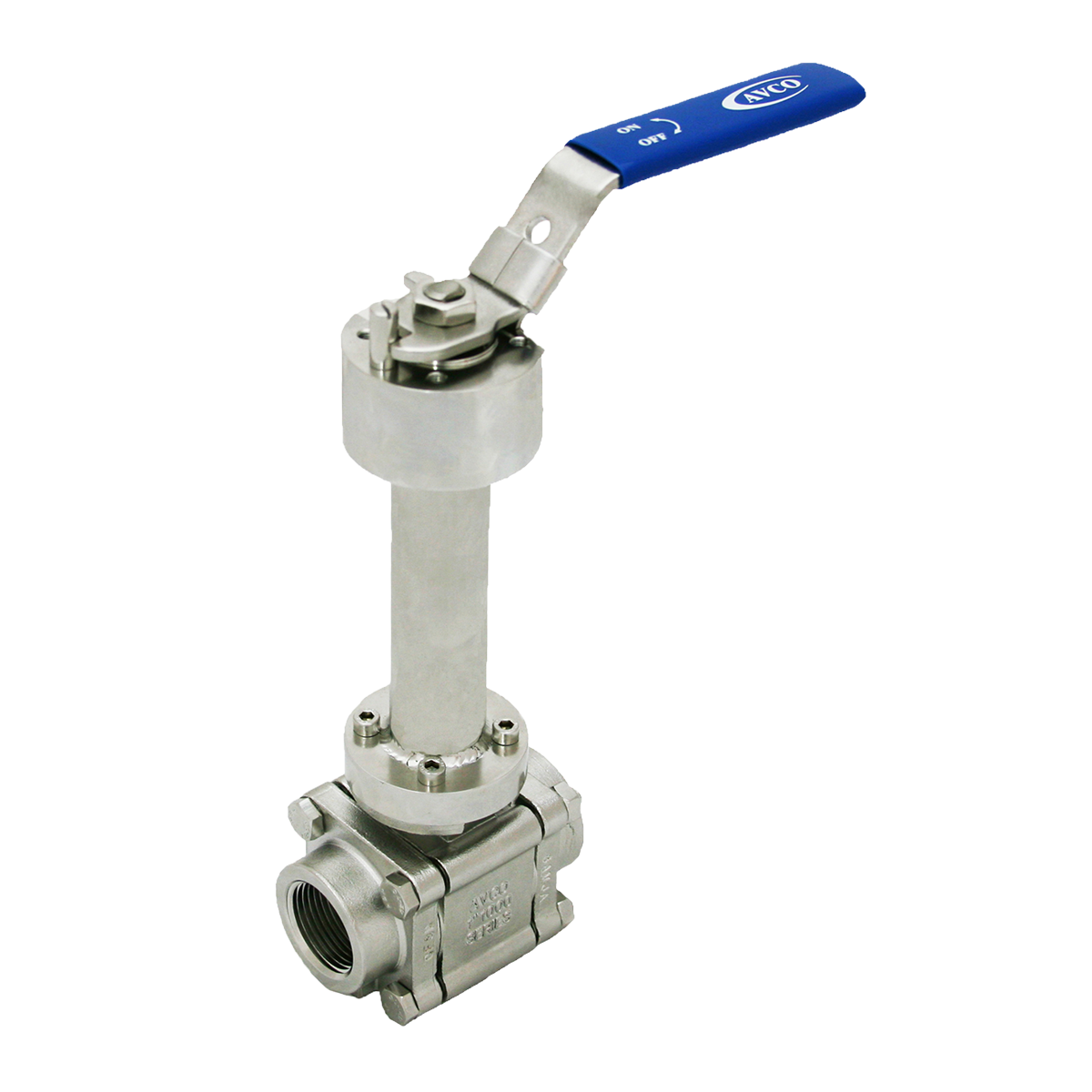

Cryogenic Floating Ball Valve (Liquid Nitrogen Ball Valve)

Ball valves have been widely used in low temperature and cryogenic applications, including LNG (Liquefied Natural Gas), which is now a preferred energy source. Eastern United offers reliable cryogenic trunnion-mounted and floating ball valves designed for extreme conditions.

Cryogenic Ball Valves: Product Overview

Cryogenic floating ball valves from Eastern United are engineered to operate effectively in extremely low temperatures, including those required for the handling of liquid nitrogen and other cryogenic gases.

Eastern United Cryo Ball Valve Specification

| Specification | Details |

|---|---|

| Sizes | 1″–10” |

| Pressure Class | 150LB–600LB |

| Materials | WCB, A105, LF2, F316, WC6, WC9, WCC, CF8, CF3, CF3M, CF8M, 4A, F51 |

| Design & Manufacturing Standards | API 6D, API 608, ASME B16.34, BS 6364, BS 5351 |

| Face-to-Face Standards | ASME B16.10, BS 558, BS12982, ISO 5752 |

| Flange Dimension Standards | ASME B16.5, ASME B16.47, ASME B16.25, ASME B16.11, BS12627 |

| Pressure Test Standards | API598, API 6D, BS12569 |

| Fire Safety Test Standards | API 6FA, API 607 |

| Certifications | ISO9001, ISO14001, ISO18001 |

| Fugitive Emissions | ISO 15848-1, API 622 |

| NACE Compliance | NACE MR 0175 |

| Valve Operator Options | Handwheel, Worm Gear, Electric Actuator, Pneumatic Actuator, Hydraulic Actuator |

| Shutoff Class | API 598 (Zero Leakage), API 6D |

| Bore Options | Full Bore, Reduced Bore |

| Process Connections | SW, NPT, BW, RF, RTJ |

📩 Get A Quote

Cryogenic Control Valve Mechanism

When closed, Eastern United’s cryogenic ball valves securely contain low-temperature gases in storage tanks. At high pressure levels, caused by extremely low temperatures, the valve opens to release pressure with controlled gas flow. Once the pressure normalizes, the valve reseals to prevent further leakage.

📩 Request A Quote

Liquid Nitrogen Ball Valve Overview

Eastern United cryogenic ball valves are specifically designed to manage and safely store substances at temperatures as low as -196°C (-321°F). They are capable of withstanding the resulting high pressures—up to Class 2500 or 750 psi.

These valves are commonly used in industrial applications involving:

- LNG and liquefied gases

- HVAC systems

- Food preservation

- Scientific cooling applications

Their robust design makes them ideal for transporting and handling liquefied industrial gases under the harshest conditions.

Cryogenic Ball Valve Design

Eastern United’s cryogenic ball valves consist of:

- Actuator: The external component used to operate the valve (manual or automated options).

- Stem: Connects actuator to ball and facilitates rotation.

- Ball: The floating ball that enables or blocks flow.

These valves feature extended bonnets (long stems) to keep the packing warm and prevent leaks. The extended design also allows easy integration with jacketing equipment or operation in space-constrained environments.

📩 Get A Quote

Applications of Eastern United Cryogenic Ball Valves

- Liquid Gas Tanks

Sealed LNG tanks fitted with cryogenic ball valves for liquid nitrogen and gas dispensing. - Power Plants

For handling and transferring LNG through insulated pipelines. - LNG Ships

Specialized marine applications requiring gas integrity during transport. - Cooling Systems

Used to control cryogenic LNG flow in scientific and high-heat operations like NMR.

Cryogenic Floating Valve Features

- PCTFE Soft Seated

- Flanged Connections

- Extended Bonnet Design

- Zero Leakage Seal (API 598)

- Handles extreme cold: -190°C to -196°C