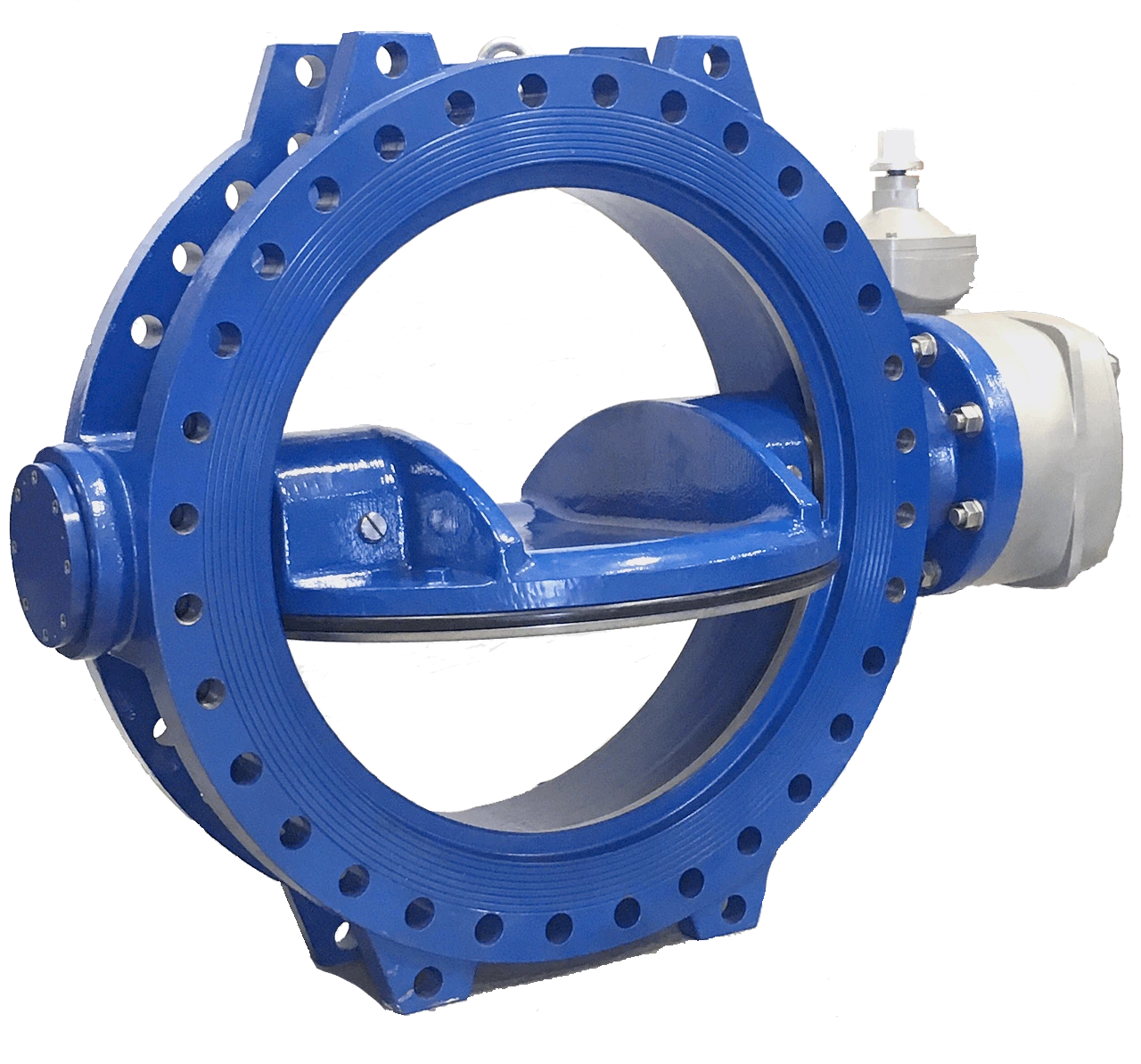

Double Eccentric Butterfly Valve

Primarily designed to meet the stringent requirements and safety levels of the oil & gas industry, this high-performance butterfly valve is available in sizes ranging from 3 inches to 24 inches (DN 80-600). This makes it ideal for a host of applications, including firewater, hydrocarbons, cargo handling, bilge and ballast systems, and utilities, to name a few.

Manufactured to ASME 150 and 300 standards, the valve features a soft polymer seat. Customers can choose from PTFE, RTFE, or UHMWPE seats, depending on their specific application and the required performance characteristics.

The valve is available in various body materials, such as carbon steel for general applications, 316 stainless steel, and duplex stainless steel for applications that require superior corrosion resistance.

Description

- K-LOK polymer and elastomer seats provide bi-directional, drop-tight shut-off in both vacuum and at full-rated differential pressure.

- The unique design ensures sealing at both high and low pressures, and in dirty services, without relying on pressure to assist sealing.

- Blow-out resistant shaft is standard on all valves for increased safety.

- The unique packing design allows use in both pressure and vacuum applications without modification or special assembly.

- Disc taper pins are positioned tangentially, half in the disc and half in the shaft, placing them in compression rather than shear, reducing the potential for failure.

- Rocker-shaped gland bridge compensates for uneven adjustment of gland nuts, reducing packing leaks.

- Integrally cast disc position stop ensures precise disc placement in the seat, enhancing seat and seal life.

- The extended neck allows for 50 mm (2″) of pipeline insulation.

- The integrally cast mounting pad enables direct mounting of actuators, eliminating the need for costly brackets and couplings.

- The flattened body bore at shaft journal ports positions shaft bearings near the disc, providing maximum shaft support and reducing wear for a longer service life.

Specifications

- Valve Size: 2″–24″

- Pressure Class: 150LB, 300LB

- Materials: WCB, CF8, CF8M, CF3M

- Design and Manufacturing Standards: API 609

- Face to Face Standards: ANSI/ASME B16.10

- Flange Dimension Standards: ANSI/ASME B16.5

- Pressure Test Standards: API 598

- Fire Safety Test Standards: –

- Quality/Product Certifications: ISO9001, ISO14001, ISO18001

- Fugitive Emissions: ISO 15848-1, API 622

- NACE: NACE MR 0103, NACE MR 0175

- Valve Operator Options: Handwheel, Worm Gear, Electric Actuator, Pneumatic Actuator, Hydraulic Actuator

- Shutoff Class: API 598 (Zero Leakage), API 6D

- Bore: Full Bore

- Process Connection Types: Wafer Type, Lug Type